Past Activites

15+ Years of Experience

The RPD group has over 15 years of experience in the development of multi-physics and multi-scale coupled codes for nuclear power plant (NPP) safety analysis. Before the creation of the KAMPS generic coupling platform, the group developed several tailored coupling systems based on different methodologies.

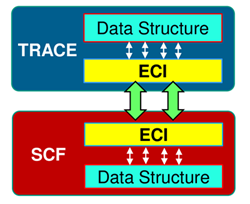

TRACE/SCF-ECI - Exterior Coupling Interface (ECI)

Socket-based communication method initially released with TRACE

Key Features:

- Each code includes its own ECI interface

- Parallel, server-less multi-task system

- Domain decomposition for spatial partitioning

- Explicit schemes for time integration

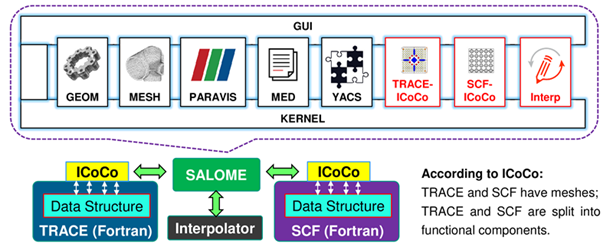

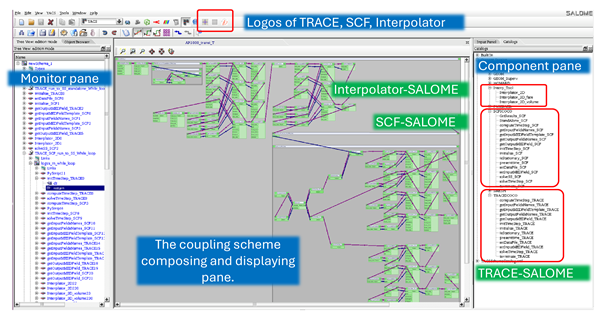

TRACE/SCF-SALOME - SALOME Platform Integration

Leverages the European open-source SALOME platform with YACS module

|

|

Key Features:

- MEDCoupling library compliance with ICoCo standard

- Substantial integration efforts required

- Graphical, modular interface

- Particularly user-friendly implementation

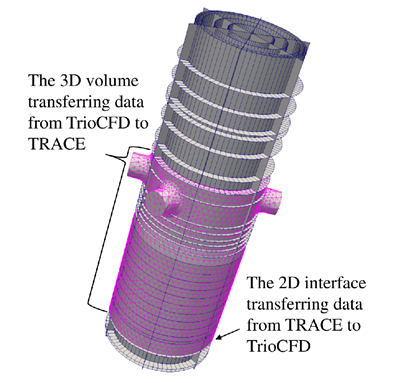

TRACE/TrioCFD - ICoCo Standard with C++ Supervisor

Domain-overlapping spatial method with custom DIAS implementation

Key Features:

- Built on ICoCo standard

- C++ supervisor coordination (distinct from KAMPS)

- 3D fields transfer between codes

- Custom Dynamic-Implicit-Additional-Source (DIAS) method

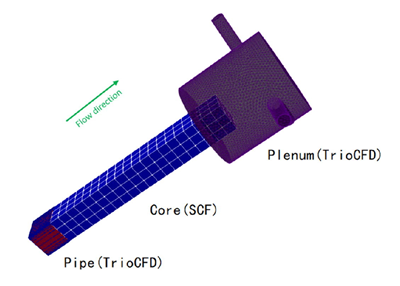

SCF/TrioCFD - Domain Decomposition Approach

Developed alongside TRACE/TrioCFD with shared supervisor architecture

Key Features:

- Adheres to ICoCo standard

- Shares C++ supervisor with TRACE/TrioCFD

- Distinct thermal-hydraulic domains simulation

- Boundary information exchange

SERPENT/SUBCHANFLOW – Internally Coupled Approach

Developed for high-fidelity core simulation using direct coupling of Monte Carlo neutronics and subchannel thermal-hydraulics.

Key Features:

-

Master–slave architecture: Serpent controls simulation, SCF provides thermal-hydraulic feedback

-

Pin-by-pin neutronics from Serpent → subchannel-level feedback from SCF

-

Iterative data exchange loop with power, temperature, density, and pressure updates

-

Applicable to steady-state, depletion, and transient scenarios

-

Validated with experiments and benchmark cases (e.g., SPERT IV, CAREM-like SMR)

SERPENT/SUBCHANFLOW/TRANSURANUS – ICoCo-Based Coupling

Three-way high-fidelity coupling system integrating neutronics, thermal-hydraulics, and thermo-mechanics within the ICoCo framework.

Key Features:

-

Fully object-oriented C++ implementation via ICoCo and MEDCoupling

-

Serpent provides pin-wise fission power; SCF computes thermal-hydraulic conditions

-

TRANSURANUS (TU) performs detailed fuel performance modeling using SCF boundary conditions

-

Semi-implicit depletion scheme ensures convergence at each burnup step

-

Applied to full-core LWR depletion simulations; verified using VVER and PWR cases

Evolution to KAMPSThese legacy developments serve as the foundation for the current KAMPS platform, allowing continuous validation and reuse of methodologies across evolving projects. The experience gained from these tailored coupling systems directly contributed to the design philosophy and technical architecture of KAMPS as a generic, flexible coupling platform. |